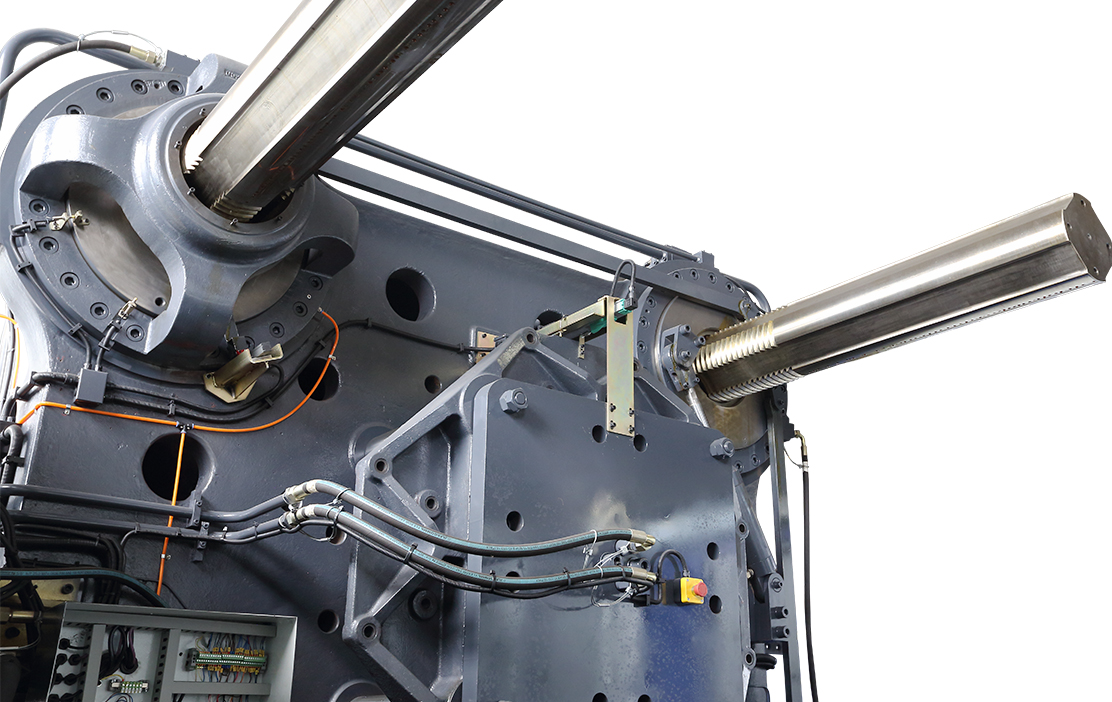

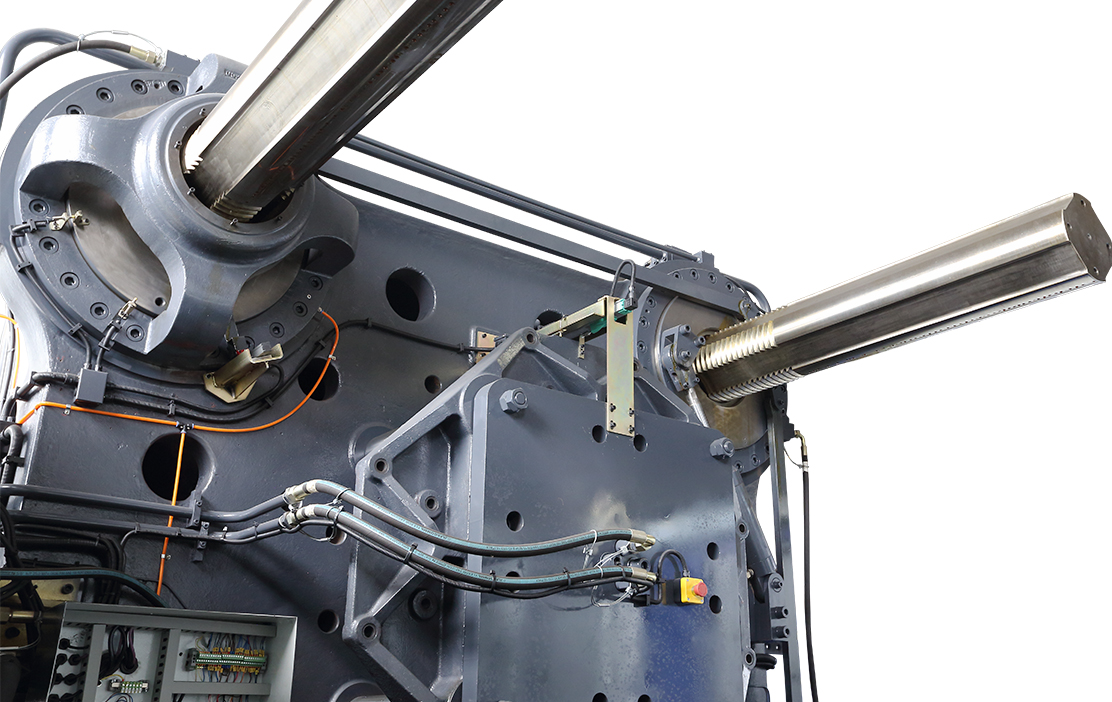

1: the integral clamping piston replaces the Harff locking mechanism and the traditional clamping cylinder structure. A large number of parts are reduced and moving parts are minimized. The reliability and service life are greatly improved. 2: a holding cylinder through 3 connecting rods driven by 4 mode-locked piston synchronous action, holding brake stability, quiet, long life. The gate position is double checked and the Factor of safety is high. 3: Tie Rod Head Plate fixed, upper tie rod two plate copper sleeve support, lower tie rod support plate support, lower tie rod and do two plate guide, Tie Rod no suspension, no droop, no sloshing. The guide span of the second plate is large and the guide rigidity is strong. Fast and stable opening and closing die for two plates. 4: Tie Rod Nut and die-locking piston mount design, protect tie rod thread, improve tie rod life. Pull Rod life-cycle design, machine non-stop pull rod. 5: high rigidity shuttering body. Make sure that the second plate opens and closes the die quickly and smoothly. 6: the clamping cylinder can be disassembled as a whole, which is easier to maintain./n/n

news

service

contact

recruitment

中文站

news

service

contact

recruitment

中文站